Why Choose a Cable Winch Puller for Heavy-Duty Lifting and Pulling?

2025-09-11

A cable winch puller, often referred to as a come-along, is a hand-operated mechanical device designed to pull, lift, or stretch heavy loads with precision. It uses a ratcheting gear system combined with a strong steel cable, allowing the operator to exert significant force with minimal manual effort. Unlike powered winches, a cable winch puller does not rely on electricity, fuel, or hydraulics—making it a versatile solution for environments where external power sources are unavailable.

The importance of a cable winch puller lies in its reliability, portability, and cost-efficiency. It has become an essential tool across industries such as construction, automotive recovery, forestry, marine transport, and even agriculture. For homeowners, it offers the ability to move heavy objects, straighten fences, or recover vehicles from difficult terrain. In professional settings, the tool ensures operational safety, accurate load control, and long-term durability.

Key reasons why professionals and DIY users choose a cable winch puller:

-

Controlled Force Application – Ratcheting systems allow step-by-step load management, preventing accidents.

-

Portability – Compact and lightweight design ensures ease of transportation.

-

Versatility – Suitable for pulling, lifting, positioning, or securing heavy loads.

-

No Power Source Needed – Functions anywhere, even in remote areas.

-

Cost-Effective – A one-time investment that delivers long-term value.

In today’s market, users demand reliability combined with technical excellence. A high-quality cable winch puller bridges this demand, enabling both professionals and individuals to complete tasks efficiently and safely.

How Does a Cable Winch Puller Work and What Are Its Key Parameters?

Understanding how a cable winch puller functions gives users confidence in its application. The tool consists of a ratchet handle, gear mechanism, steel cable, and hooks for load attachment. By pumping the ratchet handle, the operator advances the cable in controlled increments, pulling or lifting the load. The pawl mechanism ensures that the cable does not slip backward, maintaining load stability.

Below is a professional overview of standard product specifications:

| Parameter | Description |

|---|---|

| Capacity | 1 Ton – 5 Ton (varies by model, suitable for light to heavy-duty use) |

| Cable Material | Galvanized high-tensile steel for durability and corrosion resistance |

| Cable Diameter | Typically 4mm – 8mm depending on load capacity |

| Cable Length | 10 ft – 35 ft options available |

| Hooks | Forged steel with safety latches for secure load attachment |

| Gear System | Double or triple gear configuration for efficient pulling |

| Handle Length | Extended leverage design, often 12–24 inches |

| Finish | Zinc-plated or powder-coated for anti-rust protection |

| Weight | 4kg – 12kg depending on load capacity |

| Applications | Vehicle recovery, fencing, forestry, marine, construction, home use |

The most important factor when selecting a cable winch puller is capacity rating. Using a tool with a lower load rating than required can result in cable failure or gear damage. Professionals recommend choosing a model with at least 1.5 times the intended load weight for safety assurance.

Equally vital is the cable quality. Galvanized steel resists rust and enhances tensile strength, making it suitable for outdoor conditions. The ratchet handle design also plays a role in efficiency—longer handles offer better leverage, requiring less manual effort for the same pulling force.

What Are the Common Applications and Safety Considerations of Cable Winch Pullers?

A cable winch puller is used in a wide range of real-world scenarios. Its compact design allows it to outperform bulky powered winches in certain applications, particularly when mobility is crucial.

Common Applications:

-

Automotive Recovery – Retrieving vehicles stuck in mud, snow, or sand.

-

Construction – Lifting beams, aligning posts, and tensioning frameworks.

-

Agriculture – Stretching fences, pulling out tree stumps, and moving heavy machinery.

-

Forestry and Logging – Securing logs, dragging timber, and clearing land.

-

Marine and Dockyards – Securing cargo, tightening ropes, and lifting boat equipment.

-

Household and DIY – Moving large appliances, furniture, or trailers.

Safety Considerations:

-

Inspect Before Use – Check cable for frays, hooks for wear, and gears for smooth operation.

-

Load Matching – Never exceed the rated capacity of the puller.

-

Stable Anchoring – Ensure the anchor point is stronger than the pulling force required.

-

Gloves and Eye Protection – Essential to prevent injury from cable recoil or debris.

-

Slow Operation – Operate the ratchet gradually; sudden jerks may compromise control.

-

Storage and Maintenance – Store in a dry environment, lubricate gears regularly, and replace worn cables immediately.

By observing these practices, users can ensure both safety and durability of their equipment, maximizing long-term return on investment.

Why Invest in a High-Quality Cable Winch Puller?

With a wide variety of models available, choosing a premium-quality puller ensures efficiency, reliability, and safety. Inferior tools may save costs upfront but risk failure under pressure, leading to dangerous situations. High-quality models are engineered with forged hooks, reinforced gears, and corrosion-resistant finishes, extending the product lifecycle.

Two of the most frequently asked questions about cable winch pullers include:

Q1: Can a cable winch puller be used for both pulling and lifting?

Yes. A cable winch puller is designed for both pulling horizontally and lifting vertically. However, it is critical to check the manufacturer’s rated lifting capacity. Pulling requires less strain than vertical lifting, so while the same tool can perform both tasks, users should always ensure the load does not exceed capacity ratings.

Q2: How do I maintain a cable winch puller for long-term use?

Maintenance involves regular inspection of the cable for fraying, lubrication of the gear and ratchet system, and keeping the tool dry to prevent rust. Replacing worn parts immediately ensures consistent performance. A well-maintained puller can last many years, making it a cost-effective investment for both professional and home use.

Investing in the right tool not only improves task efficiency but also enhances workplace safety. A reliable cable winch puller reduces physical strain, minimizes operational risks, and ensures that every job is completed with precision.

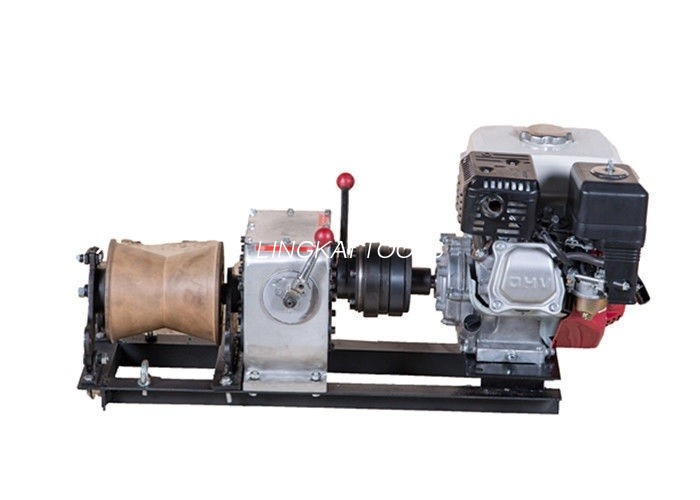

At the forefront of delivering durable, high-performance tools, Lingkai provides advanced cable winch pullers engineered for professional-grade reliability. Combining innovation with strict quality control, Lingkai ensures that users achieve maximum efficiency in heavy-duty lifting and pulling tasks. For more details about product specifications or to discuss customized solutions for your industry, contact us today.